A Refractometer-Based Method to Estimate % Alcohol by Volume (%ABV)

in

Fermenting and Finished Beers

© James

M. Gossett (July 31, 2012) Questions/Comments? ![]()

![]() Web-based Calculator

Web-based Calculator ![]() Excel-based Calculator (Download)

Excel-based Calculator (Download) ![]() Documentation

Documentation

My motivation for developing such a method is simple: I want to throw away my hydrometer! Refractometers are more convenient than hydrometers, requiring far less sample Ð a couple of drops vs. 75-90 mL. There are empirical, polynomial equations available that allow one to estimate original specific gravity (OG) and final specific gravity (FG) from initial and final refractometer readings. Thus, most brewers who wish to rely solely on their refractometers will convert readings to estimated OG and FG, and will then use those estimates in one of many available equations or web-based calculators intended for computing % alcohol by volume (%ABV) from hydrometer measurements of OG and FG.

This strikes me as unnecessarily circuitous and inelegant. The refractometer and the hydrometer are both indirect measures of what the brewer would like to know: namely, how much carbohydrate was in the initial wort and how much remains in the fermented beer. So, converting one indirect measure (the refractometer reading) to another (the hydrometer reading) is not a very satisfying solution. Furthermore, one seldom finds explanation (or demonstration of accuracy) for any of the hydrometer-based methods used to estimate %ABV. WhatÕs their underlying basis? How accurate are they?

Directions for Use

While the web-based calculator might look complicated, itÕs

really not.

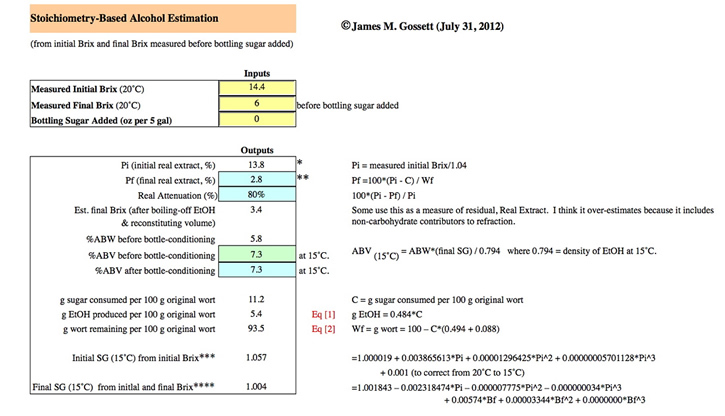

Inputs

There are only three user inputs

– the three cells with yellow background:

á

Measured Initial

Brix (20ûC) -- using a refractometer, not a hydrometer. Note: you should not use any "correction factor," here. The model is designed to receive raw Brix as input.

á

Measured Final

Brix (20ûC) before any bottling sugar is added. This Brix could be a

measurement made with refractometer during ongoing fermentation. If thatÕs what you enter into the

calculator, it will give you an estimate of where the fermentation is at that

point, in terms of %ABV and other output parameters of interest (e.g., real

extract remaining;

real attenuation; specific gravity). Again this should be raw (uncorrected) Brix from a properly calibrated refractometer.

á

Bottling Sugar

Added (ounces per 5 gallons).

Obviously, if the brew is not to be bottle-conditioned, you should enter

zero here. The model assumes bottling

sugar is corn sugar (glucose).

Outputs

There are several model outputs.

á

Pi is

an estimate of initial, real extract (% by weight). This is an estimate of the initial

carbohydrate content of the wort, not all of which

will be fermented. It differs from

initial Brix only because there can be non-carbohydrate constituents of wort that contribute to apparent Brix. The calculator assumes a commonly used,

default correction factor of 1.04. That is, Pi = initial

Brix/1.04. It must be

emphasized that Pi is not used at all in estimating

%ABV. Its

only use in the calculator is in the estimation of final extract (Pf)

and % Real Attenuation.

á

Pf is

an estimate of final, real extract (% by weight). It is a measure of the

residual, non-fermented carbohydrates.

Final,

real extract is one factor responsible for residual sweetness and Òmouth

feel.Ó It can serve as a

quality-control parameter. If one

of two intended, duplicate batches of beer has a significantly higher %ABV and lower Pf, the likely

explanation is that its mash conditions produced a wort with higher attenuation.

á

Real Attenuation

(%) is the percentage conversion of carbohydrate in the original wort by yeast via fermentation.

á

Estimated final

Brix (after boiling-off EtOH and restoring original volume

by adding water). Some brewers

use this experimental method to arrive at something akin to Pf. A

Brix measurement of the boiled-and-reconstituted sample is interpreted as

remaining, non-fermentables. The difference between such a

measure and Pf is that the Brix of the boiled-and-reconstituted

sample will include the non-carbohydrate constituents in the original wort that contributed to initial

Brix – i.e., the very constituents for which the 1.04 (or other) factor

is intended to correct. This output

parameter is reported, in case the user wants its estimate.

á

%ABW before bottle-conditioning.

á

%ABV (15ûC) before bottle-conditioning.

á

%ABV (15ûC) after bottle-conditioning.

á

g sugar consumed

per 100 g original wort.

á

g EtOH produced per 100 g original wort.

á

g wort remaining per 100 g

original wort.

á

Initial SG (15ûC),

also known as OG, estimated from initial Brix (20ûC). Note that initial SG plays no role

in the estimation of %ABW or %ABV.

á

Final SG (15ûC),

also known as FG, estimated from initial and final Brix (20ûC). Note that

the only role for FG in the calculator is its use in converting the calculated

%ABW to an estimate of %ABV.

Numerically, thatÕs not a very important role. For example, suppose %ABW

= 5.00%, density of EtOH at

15ûC is 0.794, and real FG is 1.000.

Then %ABV15ûC = 5.00%*1.000/0.794 = 6.30%. If a user mistakenly used a FG of

1.010 (a huge error of 10 points!),

then the user would estimate %ABV15ûC = 5.00%*(1.010)/0.794 = 6.36%. My point, here, is that itÕs not worth obsessing

with refinements to the polynomial expression for estimating FG.

Cautions/Suggestions

á

Make sure your refractometer is properly calibrated, and that the applied

sample and instrument are at temperatures within the automatic temperature

compensation (ATC) range of the instrument. The closer your sampleÕs temperature is

to that of the instrument, the better.

Problems arise when the user does not wait for the ATC to complete its

task. The sample is small, so it

comes to equilibrium with the instrument fairly quickly (within 30 seconds,

typically). However, the longer a

sample sits on the instrument, the greater the chance of bubble formation or

solids settling – each of which can cause error. ItÕs always better, therefore,

if the instrument and sample are at similar temperature (and that temperature

is within the ATC range), minimizing time to achieve an accurate reading. The similar temperature need not be 20ûC

for instant reading. If both

instrument and sample were, for example, 30ûC, the ATC would already have adjusted

the scale accordingly, and instant display of Brix (20ûC) would be achieved

when a 30ûC sample is loaded onto the 30ûC instrument. Delay in the ATC system

occurs only when instrument temperature changes.

á

Take care to

degas samples before measurement.

This can be done by rapidly stirring the sample after thermal

equilibration to the analytical temperature. If degassed at a much cooler temperature

than the refractometerÕs temperature, bubbles will

still form when the cool sample hits the warmer instrument, causing error.

á

Take care to

allow sample solids to settle before acquiring a subsample for refractometric measurement.

á

Calculator estimates

of %ABV will be lower than actual %ABV in the finished beer if the brew has not

really finished fermenting at the time ÒfinalÓ Brix is measured.

á

The calculator

was formulated to utilize, as final Brix, the value measured before

conditioning sugar has been added. If

you want to use the model with final Brix measured on completely finished, bottle-conditioned

beer, add a correction to initial Brix to account for the bottling

sugar Ð but then use the %ABV value for the "before bottle-conditioning" situation (otherwise, you'll be including the effects of bottling sugar twice). This correction to initial Brix is roughly 0.134 times the number of ounces of conditioning sugar used per 5 gal

of beer. For

example, suppose the measured initial Brix was 13.0, 5 oz of bottling sugar was used per 5 gallons, and the final Brix after

complete bottle-conditioning is 6.4. Then initial Brix that

should be entered to the calculator = 13.0 + 0.134*5 = 13.67, and the estimated %ABV for the finished beer is 6.3 %ABV.